Repairs for Mercedes EQ electric vehicles require specialized training and expertise due to their complex high voltage (HV) systems. Skilled technicians follow strict procedures and safety measures, including system isolation and insulated gloves, to handle HV components and minimize risks like short circuits or fires. Hybrid collisions add unique challenges, demanding well-trained personnel equipped with the latest tools to address both mechanical and electric vehicle concerns for safe, effective repairs. Safety is paramount in Mercedes EQ repair, with best practices encompassing proper training, specialized low-current tools, temporary battery disconnection, and grounding for minor damage.

In today’s transition towards electrification, understanding high voltage safety in hybrid collisions is paramount, especially for vehicles like the Mercedes EQ. This article delves into the intricacies of these advanced systems, exploring potential hazards and risks specific to Mercedes EQ electric vehicle repairs. We provide best practices for safe handling, ensuring technicians are equipped to navigate complex procedures with confidence. By adhering to robust safety protocols, we can revolutionize hybrid collision repairs, prioritizing both efficiency and worker protection.

- Unveiling High Voltage Systems in Mercedes EQ Electric Vehicles

- Potential Hazards and Risks of Hybrid Collision Repairs

- Best Practices for Safe Mercedes EQ Electric Vehicle Repair

Unveiling High Voltage Systems in Mercedes EQ Electric Vehicles

Mercedes EQ electric vehicles are renowned for their cutting-edge technology, and high voltage (HV) systems play a pivotal role in their operation. These advanced cars are equipped with sophisticated HV architectures designed to power their electric motors and support various electronic controls. Understanding these systems is crucial for maintaining and repairing Mercedes EQ electric vehicle models.

Specialized training and expertise are required to handle the intricate nature of these vehicles, especially during repair or automotive restoration processes. The high-voltage components must be meticulously handled due to the potential risks associated with electrical energy. Skilled technicians employ precise procedures and safety measures to ensure successful Mercedes EQ electric vehicle repair while mitigating any hazards related to HV systems, ensuring a smooth and safe driving experience for car paint repair and other maintenance tasks.

Potential Hazards and Risks of Hybrid Collision Repairs

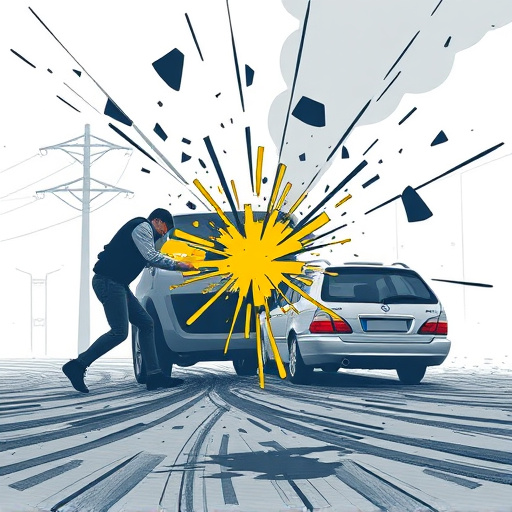

Hybrid collisions, involving both conventional and electric vehicles, present unique challenges when it comes to repairs. For instance, in the case of a Mercedes EQ electric vehicle repair, understanding potential hazards is paramount. One significant risk lies in the intricate electrical systems of these vehicles, which can be compromised during a collision. The high-voltage batteries and associated components require specialized handling and advanced safety measures due to their ability to store immense energy.

Moreover, automotive body work on hybrid vehicles demands meticulous precision. Vehicle body repair specialists must be adept at addressing both conventional mechanical issues and the specific concerns of electric vehicle systems. Improper repairs could lead to short circuits, fires, or even more severe accidents, emphasizing the need for well-trained technicians equipped with the latest knowledge and tools for collision repair services tailored to modern hybrid vehicles like Mercedes EQ models.

Best Practices for Safe Mercedes EQ Electric Vehicle Repair

When it comes to repairing a Mercedes EQ electric vehicle, safety is paramount due to the unique high-voltage systems onboard. Best practices involve ensuring proper training and certification for all technicians working on these vehicles. Specialized tools and equipment designed for low-current work are essential to prevent electrical hazards. During repair or restoration, whether it’s a classic car or a modern model like a Mercedes EQ, maintaining a safe workspace is crucial. This includes isolating the high-voltage system, using insulated gloves, and adhering to strict protocol for handling any components that could pose an electric shock risk.

For instance, in cases of minor damage such as a fender bender or vehicle dent repair, technicians should follow specific guidelines. These might include temporarily disconnecting the battery, utilizing earthleads to ground the vehicle, and ensuring all electrical systems are safe before proceeding with any aesthetic or structural repairs. Unlike a classic car restoration, where the focus is on preserving history, Mercedes EQ electric vehicle repair requires an additional layer of caution due to the integration of advanced technology and high-voltage components, making safe practices indispensable.

In understanding the intricacies of high voltage safety in hybrid collisions, especially within Mercedes EQ electric vehicle repairs, it’s clear that meticulous practices are paramount. By grasping the potential hazards and adopting best practices, technicians can ensure a secure environment for both workers and the integrity of these advanced vehicles. Navigating the unique challenges presented by electric vehicle repair requires specialized knowledge and equipment to prevent accidents and ensure the sustainable future of mobility.